Production Machining

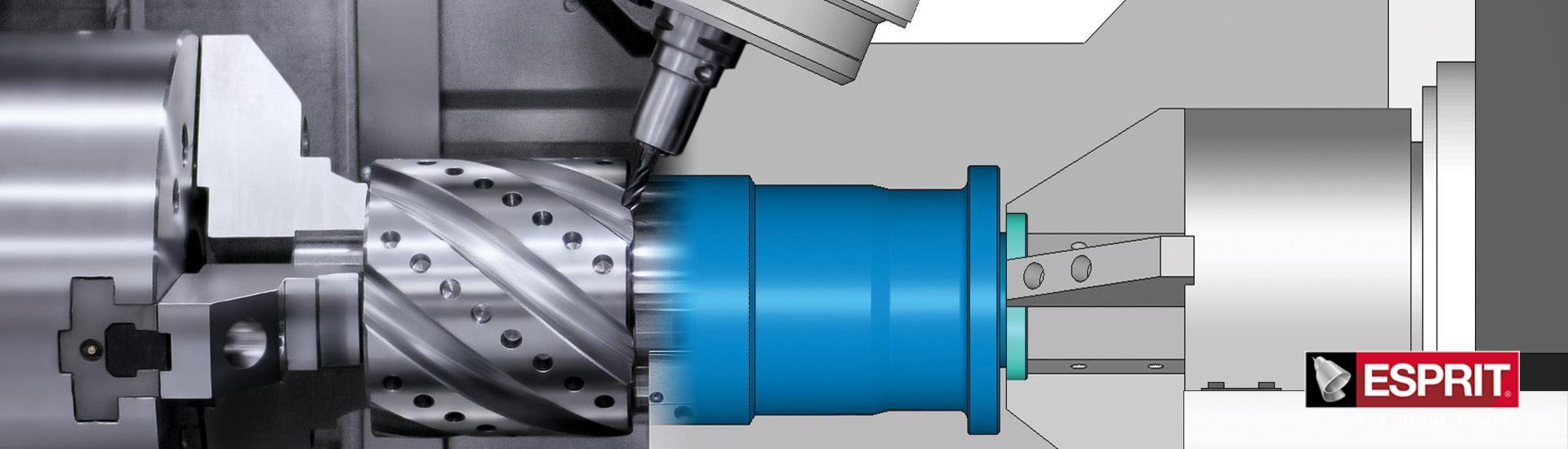

Fully utilizing the CNC machine and maximizing shop productivity

ESPRIT delivers powerful programming, accurate simulation, and machine-optimized G-code for any class of CNC machine tool including horizontal, vertical, and gantry machines. As a full-spectrum solution for high value-added parts, processes, and demanding machining applications, ESPRIT is the right choice for any industrial application, from job shop work to large-scale heavy equipment manufacturing. With ESPRIT, production machining includes the ability to combine milling, turning, and probing cycles into one program to utilize the full capability of the machine tool and maximize shop productivity.

- Powerful programming, accurate simulation, and machine-optimized G-code for any class of CNC machine tool

- Combining milling, turning, and probing cycles into one program

- Utilizing the full capability of the machine tool and maximizing shop productivity

Production Machining Features

SolidMill

Traditional 2.5-axis milling and ProfitMilling, plus:

- C-axis index and rotary milling

- A-axis, 3+1, index milling

- B-axis, 3+2, index milling

- 3rd rotary axis, 3+3, index milling

SolidTurn

- Traditional 2-axis turning cycles including ProfitTurning

- FreeForm 3-axis, 4-axis, or 5-axis

- Collinear axes

- Add-on to support programmable collinear axis

Probing

- 3+2 probing cycles for any combination of CNC machine, control, and touch probe manufacturer

Report Generator

- Shop floor reports that provide information about the machine, tooling, and machining operations

- Simultaneous multi-axis milling

Related Videos

Ask for Pricing

Used in thousands of shops all over the world, ESPRIT CAM software is a global favorite for all types of machining applications.

Ranging from small hometown job shops to multinational enterprises.