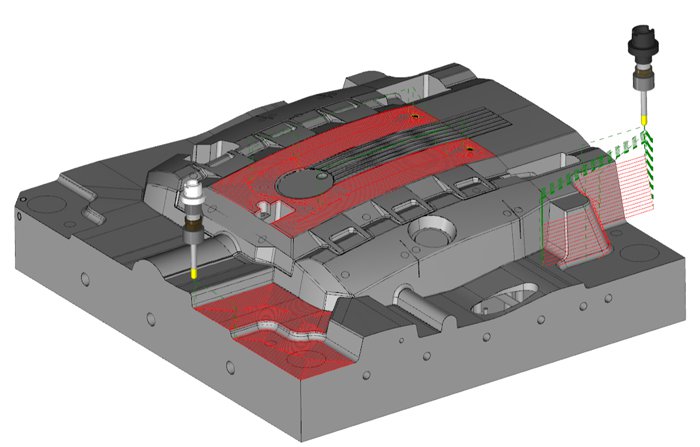

3-Axis Milling

A powerful suite of 3-axis cycles for machining complex freeform parts

ESPRIT offers a powerful suite of 3-axis machining cycles for roughing, prefinishing, finishing, and remachining of complex freeform parts. ESPRIT SolidMill FreeForm™ is extensively used by customers in mold and die, tool making, discrete parts, and model-making markets. Each of ESPRIT’s 3-axis machining cycles are optimized for machining 3D models that may include surfaces, solids, and STL geometry. With ESPRIT’s Modeless Programming™, the FreeForm cycles may be used on any configuration of mill, lathe, mill-turn, and Swiss-type machine. These 3-axis cycles may also be combined within any other ESPRIT cycle to create one complete part program for the entire part.

- A powerful suite of 3-axis cycles for machining complex freeform parts, used by customers in mold and die, tool making, discrete parts, and model-making markets

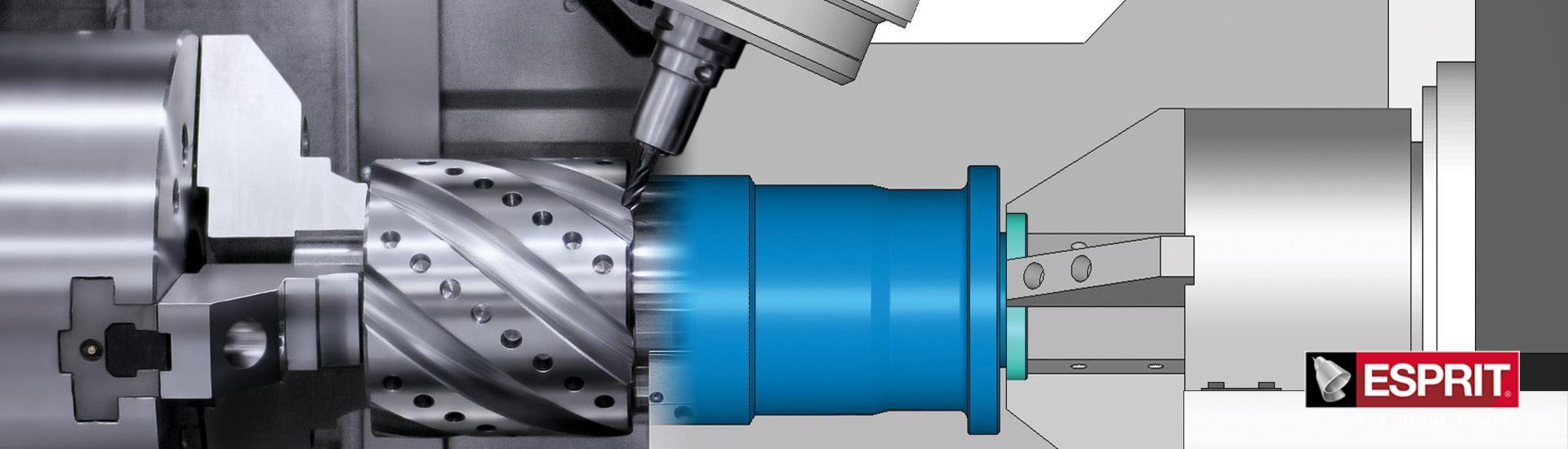

High-Performance Roughing

ESPRIT’s roughing cycles will machine workpieces down to a near net shape using the highest possible material removal rates, resulting in the shortest cycle times. ProfitMilling does this by maintaining a consistent tool engagement angle, chip load, lateral cutter force, and machine acceleration to achieve optimal results.

Prefinishing

Following roughing, ESPRIT has a variety of prefinishing cycles available to ensure the varying surfaces of the workpiece all have the exact required stock allowance. As a result, the finishing tool or tools have a constant volume of material to remove, resulting in maximizing tool life and optimal surface finishes.

Finishing

With the idea of superior surface finish in mind, the ability to select from a wide range of ESPRIT finishing strategies guarantees that a suitable strategy will be found for any surface. Select from nine different finishing cycles to machine the workpiece — use one cycle for finishing the entire part, or define containment boundaries to machine zones differently using the most appropriate cutting styles for each.

Re-machining

Maximize the part quality and minimize bench work by remachining areas where the nose radius of the finishing cutter could not follow the surface. ESPRIT’s remachining cycles automatically calculate where material remains from larger cutters and creates toolpaths for a smaller cutter to finish only these areas. Remove material in tight places without the risk of tool breakage with strategies for vertical corners, horizontal corners, and pencil tracing.

FreeForm 3-Axis Cycles

- 3D Contouring: Milling along the workpiece guided by one or more 3D curves

- Between Curves Finishing: Morphed, parallel, or perpendicular between two curves

- Concentric Finishing: Following an offset of the part boundary or a set of curves

- Corner Remachining: Removes excess material in tight corners that the previous, larger tools did not cut

- Floor Finishing: Use in combination with Z-level finishing to ensure excellent finishes on all zones of the workpiece

- Global Finishing: Combines Z-level finishing for steep areas and concentric finishing for shallow areas

- Parallel Planes: Roughing or finishing for vertical, sloped, or horizontal areas

- Parametric Finishing: Following the parametric flow lines of a selected face on the part

- Pencil Tracing: For finishing internal corners

- Radial Cycle: Roughing or finishing with the cutter radiating outward from a center point

- Spiral Cycle: A continuous outward spiral pattern for roughing or finishing

- Z-Level Finishing: Machine the entire part or selected areas using up to two tools

- Z-Level Roughing: Maintains constant loads on the cutters for smooth, high-speed toolpaths

Ask for Pricing

Used in thousands of shops all over the world, ESPRIT CAM software is a global favorite for all types of machining applications.

Ranging from small hometown job shops to multinational enterprises.