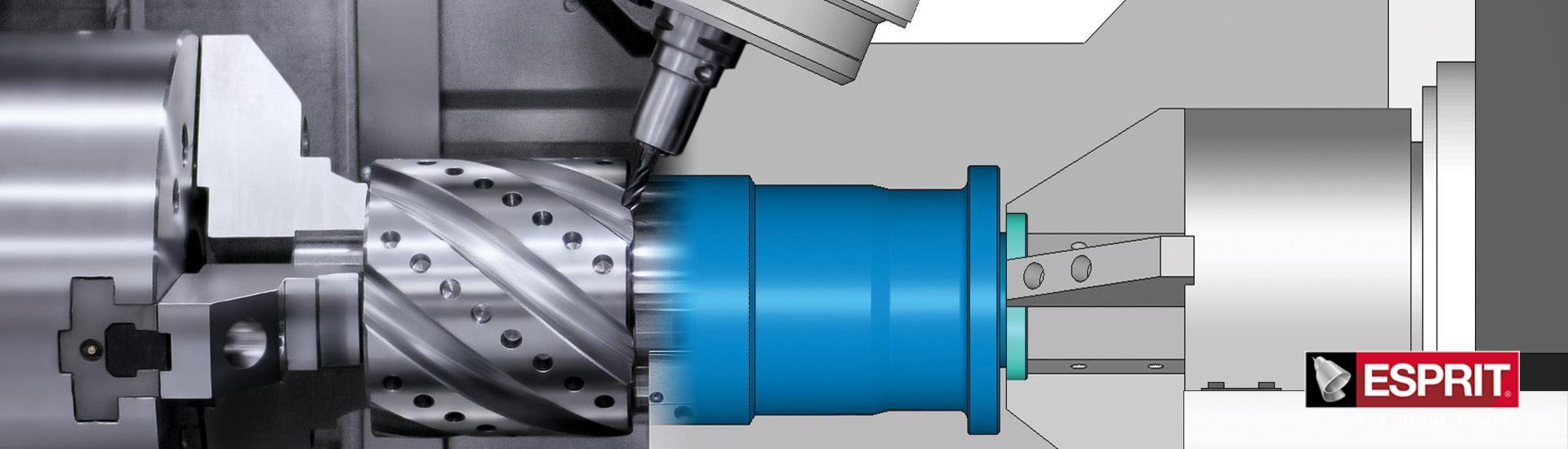

High-Speed Machining

ProfitMilling ® delivers 75% reduction in cycle time and 500% increase in tool life

High-speed machining with ESPRIT’s patented ProfitMilling cycles for 2.5-, 3-, 4-, and 5-axis roughing significantly reduces cycle times and dramatically increases tool life. The ProfitMilling strategy combines optimized, high-speed toolpath patterns, chip thinning with light radial engagements and full depths of cut, and dynamically optimized feed rates to maintain consistent chip loads and minimized cutting forces throughout the cut. This results in increased productivity and reduced operating costs.

- 75% cycle-time reduction

- 500% increase in tool life

ProfitMilling Benefits

ProfitMilling is a universal high-speed roughing cycle for 2- to 5-axis milling that requires no extra investments in specialized cutting tools, workholding, spindles, or machines. This cycle is designed to reduce loads on CNC machines, drives, and spindles, therefore it can even be used on light-duty machines. ProfitMilling is proven to work exceptionally well on most materials, with added value in Inconel, titanium, and others where the chip is hard to break. The combination of optimized toolpaths cutting at full depth with reduced radial engagement results in improved cutting performance and shorter cycle times. These techniques also transfer more heat to the chip instead of the tool and the workpiece, reducing the temperature at the cutting zone and extending tool life.

- High-speed machining for 2.5-, 3-, 4-, and 5-axis roughing

- Productivity improvements even with light- and medium-duty machine tools

- Works exceptionally well with most materials

- Reduced temperatures for longer tool life and improved surface quality

- 75% cycle-time reduction

- 500% increase in tool life

How ProfitMilling Works?

The ProfitMilling cycle’s dramatic improvements in cycle time and tool life are the result of a patented method of cycle optimization that produces consistent chip loads and reduced cutting forces. The optimized, high-speed toolpath patterns reduce the need for rapid machine accelerations and abrupt changes in direction which would otherwise negatively affect chip loads and increase cutting forces. A chip thinning technique cuts at full axial depth and reduced radial width, allowing significantly higher feed rates. To maintain the programmed chip load throughout the cut, the ProfitMilling cycle dynamically adapts the actual feed rate to account for the geometry and toolpath variances. Offset, spiraling, and trochoidal motions reduce the need for rapid machine acceleration or deceleration, increasing the overall velocity. Therefore, the programmed feed rate

is easier for the CNC to attain and overall material removal rates are maximized.

- Optimized, high-speed toolpath patterns

- Chip thinning with light radial engagement and full depth of cut

- Compensation for geometric and toolpath variances with dynamic feed rates

- Chip evacuation using spiraling to open cavities

- Trochoidal motions open channels and slots

- Offsets of part boundary for machining "open" zones

- Bottom-up strategy for pocketing and Z-level roughing

Traditional Roughing

Cycle times are longer as machines must run at conservative cutting speeds to account for chip

load and acceleration inconsistencies.

- Sharp corners result in high cutting forces and acceleration rates, and "jerks"

- Full-width slotting overloads the cutter

- Varying high tool engagement angles increase chip loads

- Constant centerline feed rates result in varying chip loads

- Cutting at multiple incremental depths increases cycle times

Roughing with ProfitMilling

High-speed cycle allows for deeper cuts while increasing cutting speeds, resulting in shorter cycle times and longer tool life.

- Initial spiral out motion creates a larger opening faster for better chip evacuation

- Smooth toolpath patterns with blended transitions

- Trochoidal slotting strategy for a constant chip load

- Corner picking to eliminate chatter and provide a constant tool-engagement angle

- Optional slotting strategy with reduced incremental depth passes

- Optimized transitional moves with small Z lifts to reduce drag

- Full-depth cuts reduce multiple incremental depth passes

- Dynamically optimized feed rate during the cut

Using ProfitMilling

- Double or triple tool-manufacture recommended feed, speed and surface speed in MMPT or IPT

- For hard metals, use a radial engagement between 27% and 37%

- For softer materials, use engagement just under 90%

- The ProfitMilling toolpath puts most of the generated heat into the chip and away from the part and tool

- Use tools with a high flute count — coolant is discouraged as it can increase thermal shock on the cutting edge

- Check your machine’s control settings to ensure programmed feed rates are being attained

Have a Look

Ask for Pricing

Used in thousands of shops all over the world, ESPRIT CAM software is a global favorite for all types of machining applications.

Ranging from small hometown job shops to multinational enterprises.